This is an introduction to rigid pavement design for engineers. It is not intended as definitive treatise, and it does not encompass the design of flexible pavements.Engineers are cautioned that much of pavement design is governed by codes, specifications and practices of public agencies. Engineers must always determine the requirements of the regulatory authority within whose jurisdiction specific projects fall.

2. RIGID PAVEMENT DESIGN

2.1 Soil Classification and Tests

All soils should be classified according to the Unified Soil Classification System (USGS) as given in ASTM D 2487. There have been instances in construction specifications where the use of such terms as "loam," “gumbo,” "mud," and "muck" have resulted in misunderstandings. These terms are not specific and are subject to different interpretations throughout the United States. Such terms should not be used. Sufficient investigations should be performed at the proposed site to facilitate the description of all soils that will be used or removed during construction in accordance with ASTM D 2487; any additional descriptive information considered pertinent should also be included. If Atterberg limits are a required part of the description, as indicated by the classification tests, the test procedures and limits should be referenced in the construction specifications.

2.2 Compaction

2.2.1General

|

| Table 2-1 Modulus of Soil Reaction |

|

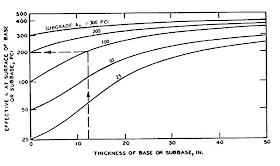

| Figure 2-1 Effect of Base-Course Thickness on Modulus of Soil Reaction |

Compaction improves the stability of the subgrade soils and provides a more uniform foundation for the pavement. ASTM D 1557 soil compaction test conducted at several moisture contents is used to determine the compaction characteristics of the subgrade soils. This test method should not be used if the soil contains particles that are easily broken under the blow of the tamper unless the field method of compaction will produce a similar degradation. Certain types of soil may require the use of a laboratory compaction control test other than the above-mentioned compaction test. The unit weight of some types of sands and gravels obtained using the compaction method above may be lower than the unit weight that can be obtained by field compaction; hence, the method may not be applicable. In those cases where a higher laboratory density is desired, compaction tests are usually made under some variation of the ASTM D 1557 method, such as vibration or tamping (alone or in combination) with a type hammer or compaction effort different from that used in the test.

2.2.2 Requirements

For all subgrade soil types, the subgrade under the pavement slab or base course must be compacted to a minimum depth of 6 inches. If the densities of the natural subgrade materials are equal to or greater than 90 percent of the maximum density from ASTM D 1557, no rolling is necessary other than that required to provide a smooth surface. Compaction requirements for cohesive soils (LL > 25; PI > 5) will be 90 percent of maximum density for the top 6 inches of cuts and the full depth of fills. Compaction requirements for cohesionless soils (LL < 25: PI <5) will be 95 percent for the top 6 inches of cuts and the full depth of fills. Compaction of the top 6 inches of cuts may require the subgrade to be scarified and dried or moistened as necessary and recompacted to the desired density.

2.2.3 Special Soils

Although compaction increases the stability and strength of most soils, some soil types show a marked decrease in stability when scarified, worked, and rolled. Also, expansive soils shrink excessively during dry periods and expand excessively when allowed to absorb moisture. When any of these types are encountered, special treatment will be required. For nominally expansive soils, water content, compaction effort, and overburden should be determined to control swell. For highly expansive soils, replacement to depth of moisture equilibrium, raising grade, lime stabilization, prewetting, or other acceptable means of controlling swell should be considered.

2.3 Treatment of Unsuitable Soils

Soils not suitable for subgrade use should be removed and replaced or covered with soils which are suitable. The depth to which such adverse soils should be removed or covered depends on the soil type, drainage conditions, and depth of freezing temperature penetration and should be determined by the engineer on the basis of judgment and previous experience, with due consideration of the traffic to be served and the costs involved. Where freezing temperatures penetrate a frost-susceptible subgrade, special design procedures should be followed.

In some instances, unsuitable or adverse soils may be improved economically by stabilization with such materials as cement, flyash, lime, or certain chemical additives, whereby the characteristics of the composite material become suitable for subgrade purposes. However, subgrade stabilization should not be attempted unless the costs reflect corresponding savings in base-course, pavement, or drainage facilities construction.

2.4 Determination of Modulus of Subgrade Reaction

For the design of rigid pavements in those areas where no previous experience regarding pavement performance is available, the modulus of subgrade reaction k to be used for design purposes is determined by the field plate-bearing test. This test procedure and the method for evaluating its results are not part of this discussion. Where performance data from existing rigid pavements are available, adequate values for k can usually be determined on the basis of consideration of soil type, drainage conditions, and frost conditions that prevail at the proposed site. Table 2-1 presents typical values of k for various soil types and moisture conditions. These values should be considered as a guide only, and their use in lieu of the field plate-bearing test, although not recommended, is left to the discretion of the engineer. Where a base course is used under the pavement, the k value on top of the base is used to determine the modulus of soil reaction on top of the base. The plate-bearing test may be run on top of the base, or figure 2-1 may be used to determine the modulus of soil reaction on top of the base. It is good practice to confirm adequacy of the k on top of the base from figure 2-1 by running a field plate-load test.

3. RIGID PAVEMENT BASE COURSES

3.1 General Requirements

Base courses may be required under rigid pavements for replacing soft, highly compressible or expansive soils and for providing the following:

• Additional structural strength.

• More uniform bearing surface for the pavement.

• Protection for the subgrade against detrimental frost action.

• Drainage.

• Suitable surface for the operation of construction equipment, especially slipform pavers.

|

| Figure 3-1 Design Curves for Plain Concrete Streets and Roads, and RCC |

|

| Figure 3-2 Design Curves for Plain Concrete Parking and Storage Areas |

Use of base courses under a rigid pavement to provide structural benefit should be based on economy of construction. The first cost is usually less for an increase in thickness than for providing a thick base course. However, thick base courses have often resulted in lower maintenance costs since the thick base course provides stronger foundation and therefore less slab movement. A minimum basecourse thickness of 4 inches is required over subgrades that are classified as OH, CH, CL, MH, ML, and OL to provide protection against pumping. In certain cases of adverse moisture conditions (high water table or poor drainage), SM and SC soils also may require base courses to prevent pumping. The designer is cautioned against the use of fine-grained material for leveling courses or choking open-graded base courses since this may create a pumping condition. Positive drainage should be provided for all base courses to ensure water is not trapped directly beneath the pavement since saturation of these layers will cause the pumping condition that the base course is intended to prevent.

3.2 Materials

If conditions indicate that a base course is desirable under a rigid pavement, a thorough investigation should be made to determine the source, quantity, and characteristics of the available materials. A study should also be made to determine the most economical thickness of material for a base course that will meet the requirements. The base course may consist of natural, processed, or stabilized materials. The material selected should be the one that best accomplishes the intended purpose of the base course. In general, the base- course material should be a well graded, high-stability material. In this connection all base courses to be placed beneath concrete pavements for military roads and streets should conform to the following

requirements:

requirements:

• Percent passing No.10 sieve; Not more than 85.

• Percent passing No.200 sieve: Not more than 15.

• Plasticity index: Not higher than 6.

Where local experience indicates their desirability, other control limitations such as limited abrasion loss may be imposed to ensure a uniform high quality base course.

3.3 Compaction

Where base courses are used under rigid pavements, the basecourse material should be compacted to a minimum of 95 percent of the maximum density. The engineer is cautioned that it is difficult to compact thin base courses to high densities when they are placed on yielding subgrades.

3.4 Frost Requirements

In areas where subgrade soils are subjected to seasonal frost action detrimental to the performance of pavements, the requirements for basecourse thickness and gradation will follow the criteria in this discussion.

4. CONCRETE PAVEMENT

4.1 Mix Proportioning and Control

Normally, a design flexural strength at 28-day age will be used for the pavement thickness determination. Should it be necessary to use the pavements at an earlier age, consideration should be given to the use of a design flexural strength at the earlier age or to the use of high early strength cement, whichever is more Mix proportion or pavement thickness may have to economical. Flyash gains strength more slowly than cement, so that if used it may be desirable to select a strength value at a period other than 28 days if time permits.

4.2 Testing

The flexural strength of the concrete and lean concrete base will be determined in accordance with ASTM C 78. The standard test specimen will be a 6- by 6-inch section long enough to permit testing over a span of 18 inches. The standard beam will be used for concrete with the maximum size aggregate up to 2 inches. When

aggregate larger than the 2-inch nominal size is used in the concrete, the cross sectional dimensions of the beam will be at least three times the nominal maximum size of the aggregate, and the length will be increased to at least 2 inches more than three times the depth.

aggregate larger than the 2-inch nominal size is used in the concrete, the cross sectional dimensions of the beam will be at least three times the nominal maximum size of the aggregate, and the length will be increased to at least 2 inches more than three times the depth.

4.3 Special Conditions

Mix proportion or pavement thickness may have to be adjusted due to results of concrete tests. If the tests show a strength gain less than predicted or retrogression in strength, then the pavement would have to be thicker. If the concrete strength was higher than predicted, then the thickness may be reduced. Rather than modifying the thickness required as a result of tests on the concrete, the mix proportioning could be changed to increase or decrease the concrete strength, thereby not changing the thickness.

5. PLAIN CONCRETE PAVEMENT DESIGN

5.1 Roller-Compacted Concrete Pavements

Roller-compacted concrete pavements (RCCP) are plain concrete pavements constructed using a zero-slump portland cement concrete mixture that is placed with an AC paving machine and compacted with

vibratory and rubber-tired rollers.

vibratory and rubber-tired rollers.

5.2 Design Procedure

For convenience in determining design requirements, the entire range of vehicle loadings and traffic intensities anticipated during the design life of pavements for the various classifications of roads and streets has been expressed as an equivalent number of repetitions of an 18,000- pound single-axle loading. To further simplify the design procedure, the range of equivalent repetitions of the basic loading thus determined has been designated by a numerical scale defined as the pavement design index. This index extends from 1 through 10 with an increase in numerical value indicative of an increase in pavement design requirements. Values for the design index are determined using standard procedures. Once the design index has been determined the required thickness of plain concrete pavement is then obtained from the design chart presented in figure 5-1 for roads and streets. Figure 5-2 is used to determine the thickness of parking and storage areas except that the thickness of rollercompacted concrete parking and storage areas will be designed using figure 5-1. These

design charts are graphical representations of the interrelation of flexural strength, modulus of subgrade reaction k, pavement thickness, and repetitions (design index) of the basic 18,000-pound single-axle loading. These design charts are based on the theoretical analyses supplemented by empirical modifications determined from accelerated traffic tests and observations of pavement behavior under actual service conditions. The design charts are entered using the 28-day flexural strength of the concrete.A horizontal projection is then made to the right to the design value for k. A vertical projection is then made to the appropriate design-index line. A second horizontal projection to the right is then made to intersect the scale of pavement thickness. The dashed line shown on curves is an example of the correct use of the curves. When the thickness from the design curve indicates a fractional value, it will be rounded up to the next ½-inch thickness. All plain concrete pavements will be uniform in cross-sectional thickness. Thickened edges are not normally required since the design is for free edge stresses. The minimum thickness of plain concrete for any military road, street, or open storage area will be 6 inches.

design charts are graphical representations of the interrelation of flexural strength, modulus of subgrade reaction k, pavement thickness, and repetitions (design index) of the basic 18,000-pound single-axle loading. These design charts are based on the theoretical analyses supplemented by empirical modifications determined from accelerated traffic tests and observations of pavement behavior under actual service conditions. The design charts are entered using the 28-day flexural strength of the concrete.A horizontal projection is then made to the right to the design value for k. A vertical projection is then made to the appropriate design-index line. A second horizontal projection to the right is then made to intersect the scale of pavement thickness. The dashed line shown on curves is an example of the correct use of the curves. When the thickness from the design curve indicates a fractional value, it will be rounded up to the next ½-inch thickness. All plain concrete pavements will be uniform in cross-sectional thickness. Thickened edges are not normally required since the design is for free edge stresses. The minimum thickness of plain concrete for any military road, street, or open storage area will be 6 inches.

6. REINFORCED CONCRETE PAVEMENT DESIGN

6.1 Application

Under certain conditions, concrete pavement slabs may be reinforced with welded wire fabric or formed bar mats arranged in a square or rectangular grid. The advantages of using steel reinforcement include a reduction in the required slab thickness, greater spacing between joints, and reduced differential settlement due to nonuniform support or frost heave.

6.1.1 Subgrade conditions

Reinforcement may reduce the damage resulting from cracked slabs. Cracking may occur in rigid pavements founded on subgrades where differential vertical movement is a definite potential. An example is a foundation with definite or borderline frost susceptibility that cannot feasibly be made to conform to conventional frost design requirements.

6.1.2 Economic considerations

In general, reinforced concrete pavements will not be economically competitive with plain concrete pavements of equal load-carrying capacity, even though a reduction in pavement thickness is possible. Alternate bids, however, should be invited if reasonable doubt exists on this point.

6.1.2.1 Plain concrete pavements

In otherwise plain concrete pavements, steel reinforcement should be used for the following conditions:

• Odd-shaped slabs. Odd-shaped slabs should be reinforced in two directions normal to each other using a minimum of 0.05 percent of steel in both directions. The entire area of the slab should be reinforced. An odd-shaped slab is considered to be one in which the longer dimension exceeds the shorter dimension by more than 25 percent or a slab which essentially is neither square nor rectangular. Figure 6-1 includes examples of reinforcement required in oddshaped slabs.

|

| Figure 6-1 Typical Layout of Joints at Intersection |

• Mismatched joints. A partial reinforcement or slab is required where the joint patterns of abutting pavements or adjacent paving lanes do Dot match, unless the pavements are positively separated by an expansion joint or slip-type joint having less than ¼-inch bond-breaking medium. The pavement slab directly opposite the mismatched joint should be reinforced with a minimum of 0.05 percent of steel in directions normal to each other for a distance of 3 feet back from the juncture and for the full width or length of the slab in 8 direction normal to the mismatched joint. Mismatched joints normally will occur at intersections of pavements or between pavement and fillet areas as shown in figure 6-1.

6.2 Design Procedure

6.2.1 Thickness design on unbound base or subbase

|

| Figure 6-2 Reinforced Rigid Pavement Design |

The design procedure for reinforced concrete pavements uses the principle of allowing a reduction in the required thickness of plain concrete pavement due to the presence of the steel reinforcing. The design procedure has been developed empirically from a limited Dumber of prototype test pavements subjected to accelerated traffic testing. Although some cracking will occur in the pavement under the design traffic loadings, the steel reinforcing will hold the cracks tightly closed. The reinforcing will prevent spalling or faulting at the cracks and provide a serviceable pavement during the anticipated design life. Essentially, the design method consists of determining the percentage of steel required, the thickness of reinforced concrete pavement, and the minimum allowable length of the slabs. Figure 6-2 presents a graphic solution for the design of reinforced concrete pavements. Since the thickness of a reinforced concrete pavement is a function of the percentage of steel reinforcing, the designer may determine either the required percentage of steel for a predetermined thickness of pavement or the required thickness of pavement for a predetermined percentage of steel. In either case, it is necessary to determine the required thickness of plain concrete pavement by the method outlined. The plain concrete thickness h (to the nearest 0.1 inch) is used to enter the nomograph in Figure 6-2. A straight line is then drawn from the value of hd to the value selected for either the reinforced concrete thickness hr or the percentage of reinforcing steel S. It should be noted that the S value indicated by figure 6-2 is the percentage to be used in the longitudinal direction only. For normal designs, the percentage of steel

used in the transverse direction will be one- half of that to be used in the longitudinal direction. In fillets, the percent steel will be the same in both directions. Once the h and S values have been determined, the maximum allowable slab length L is obtained from the intersection of the straight line and the scale for L. Difficulties may be encountered in sealing joints between very long slabs because of volumetric changes caused by temperature changes.

used in the transverse direction will be one- half of that to be used in the longitudinal direction. In fillets, the percent steel will be the same in both directions. Once the h and S values have been determined, the maximum allowable slab length L is obtained from the intersection of the straight line and the scale for L. Difficulties may be encountered in sealing joints between very long slabs because of volumetric changes caused by temperature changes.

6.2.2 Thickness design on stabilized base or subgrade

To determine the thickness requirements for reinforced concrete pavement on a stabilized foundation, it is first

necessary to determine the thickness of plain concrete pavement required over the stabilized layer using procedures set forth above. This thickness of plain concrete is then used with figure 6-2 to design the reinforced in the same manner discussed above for nonstabilized foundations.

necessary to determine the thickness of plain concrete pavement required over the stabilized layer using procedures set forth above. This thickness of plain concrete is then used with figure 6-2 to design the reinforced in the same manner discussed above for nonstabilized foundations.

6.3 Limitations

The design criteria for reinforced concrete pavement for roads and streets may be subject to the following limitations.

• No reduction in the required thickness of plain concrete pavement should be allowed for percentages of longitudinal steel less than 0.05 percent.

• No further reduction in the required thickness of plain concrete pavement should be allowed over that indicated in figure 6-2 for 0.5 percent longitudinal steel, regardless of the percentage of steel used.

• The maximum length L of reinforced concrete pavement slabs should not exceed 75 feet regardless of the percentage of longitudinal steel, yield strength of the steel, or thickness of the pavement. When long slabs are used, special consideration must be given to joint design and sealant requirements.

|

| Figure 6-3 (Part 1) Design Details of Reinforced Rigid Pavement with Two Traffic Lanes |

|

| Figure 6-3 (Part 2) Design Details of Reinforced Rigid Pavement with Two Traffic Lanes |

• The minimum thickness of reinforced concrete pavements should be 6 inches, except that the minimum thickness for driveways will be 5 inches and the minimum thickness for reinforced overlays over rigid pavements will be 4 inches.

6.4 Reinforcing Steel

6.4.1 Type of reinforcing steel

The reinforcing steel may be either deformed bars or welded wire fabric. Deformed bars should conform to the requirements of ASTM A 615, A 616, or A 617. In general, grade 60 deformed bars should be specified, but other grades may be used if warranted. Fabricated steel bar mats should conform to ASTM A

184. Cold drawn wire for fabric reinforcement should conform to the requirements of requirements of ASTM A 82, and welded steel wire fabric to ASTM A 185. The use of epoxy coated steel may be considered in areas where corrosion of the steel may be a problem.

184. Cold drawn wire for fabric reinforcement should conform to the requirements of requirements of ASTM A 82, and welded steel wire fabric to ASTM A 185. The use of epoxy coated steel may be considered in areas where corrosion of the steel may be a problem.

6.4.2 Placement of reinforcing steel

The reinforcing steel will be placed at a depth of ¼hd + 1 inch from the surface of the reinforced slab. This will place the steel above the neutral axis of the slab and will allow clearance for dowel bars. The wire or bar sizes and spacing should be selected to give, as nearly as possible, the required percentage of steel per foot of pavement width or length. In no case should the percent steel used be less than that required by figure 6-2. Two layers of wire fabric or bar mat, one placed directly on top of the other, may be used to obtain the required percent of steel; however, this should only be done when it is impracticable to provide the required steel in one layer. If two layers of steel are used, the layers must be fastened together (either wired or clipped) to prevent excessive separation during concrete placement. When the reinforcement is installed and concrete is to be placed through the mat or fabric, the minimum clear spacing between bars or wires will be 1½ times the maximum size of aggregate. If the strike-off method is used to place the reinforcement (layer of concrete placed and struck off at the desired depth, the reinforcement placed on the plastic concrete, and the remaining concrete placed on top of the reinforcement), the minimum spacing of wires or bars will not be less than the maximum size of aggregate. Maximum bar or wire spacing or slab thickness shall not exceed 12 inches. The bar mat or wire fabric will be securely anchored to prevent forward creep of the steel mats during concrete placement and finishing operations. The reinforcement shall be fabricated and placed in such a manner that the spacing between the longitudinal wire or bar and the longitudinal joint, or between the transverse wire or bar and the transverse joint, will not exceed 3 inches or one-half of the wire or bar spacing in the fabric or mat.

The wires or bars will be lapped as follows:

• Deformed steel bars will be overlapped for a distance of at least 24 bar diameters measured from the tip of one bar to the tip of the other bar. The lapped bars will be wired or otherwise securely fastened to prevent separation during concrete placement.

• Wire fabric will be overlapped for a distance equal to at least one spacing of the wire in the fabric or 32 wire diameters, whichever is greater. The length of lap is measured from the tip of one wire to the tip of the other wire normal to the lap. The wires in the lap will be wired or otherwise securely fastened to prevent separation during concrete placement.

|

| Figure 6-4 Design Details of Reinforced Rigid Pavement with Traffic and Parking Lanes |